| Home > Robots > Alexander > August | |

| August | |

![[August]](or-aug.gif)

In early August I started having noise problems with the integration of the PlayStation hand controller and the R/C transmitter. I tried a couple of sneaky methods to get the data reliably to the onboard controller, but nothing worked successfully. So I had to switch to Plan B and spend another $600 on a second R/C rig plus a ton of Tekin Rebel speed contollers and give the Edger it's very own control transmitter. This had the unfortunate side effect of throwing weapon officer Dave off in the control scheme, as he'd been practicing for two months with the PlayStation. And it showed at the event.

Around the same time, I weighed the Ax and learned that it was 3.5 lb. overweight. After recovering from the shock and two near-allnighters of machining I managed to ditch the weight and bring it back under control. This ate up my "slack week" causing me to once again return to Robot Wars tired, stressed and with a non-empty ToDo list.

|

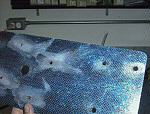

About the only structural modification I made to the Ax in August was to replace the Aluminum baseplate of the Edger with a 4mm thick chunk of carbon composite. This stuff is a trip, posessing the equivalent strength of Al at half the weight. Downside is that it can't hold threads and is a major pain to drill and cut. A 24" by 18" sheet costs about $120 from Kinetic Compostites. Upside is that it has the cool Stealth Fighter persona about it. |

|

We sold out of event T-shirts this year, but I've ordered another two dozen. They are black, 100% cotton (Hanes beefy-T) available only in size XL. Send me e-mail if you didn't get one there and/or want one now. The price is $12 for the shirt plus $3 for shipping, handling and dealer installed optional equipment. |

|

We took some damage at the event to the tune of about $500. There was some talk of inviting the Alexander to Great Britian in November to participate in the big Robot Wars UK competition. Whether I fix the Ax or not depends on whether this opportunity materializes or not. I'm going to wait and see. |

| How did we do in the arena? Terribly. The Sullivan drive motors overheated and burned up; it was a mistake to switch from torque to speed this year. The main acutuator for the Edger broke every time; turns out those units are great at extending but come apart when pulling under load. So much for my "know every part of your robot" philosophy. The video link worked great though! Well, that's pretty much it for the Alexander project. With a complete rework of the drive base this robot could still do pretty well in the middleweights. Maybe a future project! |