| by William

Billingsley (Team 6061)

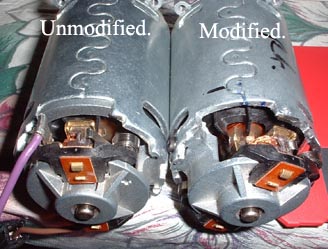

I heard a lot about the 18v Dewalt motors

before I bought some for my robot. My bot has two wheels and

when I installed my motors I noticed it was hard to drive in

a straight line. These motors have advanced timing in the CCW

(counter-clockwise) direction of about 15 degrees. In a tank

style setup, the advanced timing caused my bot to run faster

on the left and slower on the right side when going forward

and faster on the right and slower on the left when going in

reverse. You could re-time both motors to neutral but I decided

to re-time one motor to "match" the other but in the opposite

direction so I'll end up with two motors that when put face

to face will go "fast" forward and "slower" in reverse. Phasing

is adjusting the position of the motor brushes in relation to

the magnets.

Here's how I did it:

| 1. |

First I removed the brushes from the motor

with a screwdriver (see photo 1). |

|

| 2. |

Then I removed the material that keeps the

motor together. I used some wire cutters and a Dremel tool

to do this. Make sure you tape the motor openings so metal

fillings don't drop inside. A can of air will blow out the

motor when your done. I also used wire cutters to "pinch"

some areas. Take your time and make sure all material is

removed. |

|

|

| 3. |

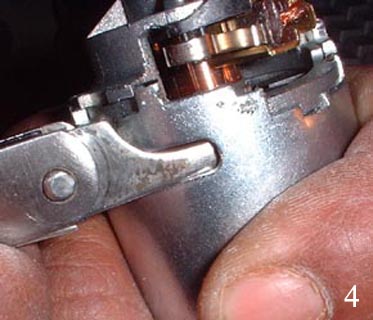

Now you can pry the top up by placing a tool

inside the vent and prying on the raised pry point (see

photo 4). Be careful and pry on each four points a little

at a time. You should see the brush holder coming off. Remove

then put aside. I ended up breaking the two arm parts off

of the brush holder so be careful. |

|

|

| 4. |

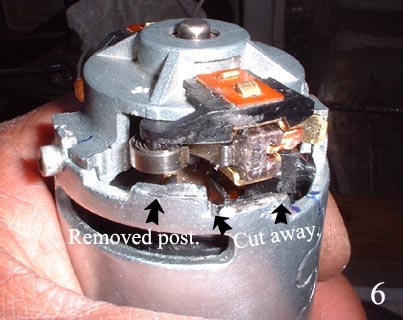

To turn the brushes approximately 30 degrees

clock-wise you have to make room for the brushes in the

motor housing. Use a cutting wheel and remove one post from

each side of the motor housing but make sure you remove

the ones on the right as you hold the motor in your hand.

Then enlarge the brush opening by cutting out the area to

the left of the existing opening (see photo 6). |

|

| 5. |

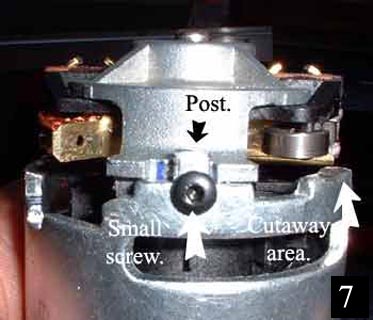

Now you can put the brush holder back on and

line it up on the post that remains. You can adjust the

degree of timing you want depending on where you drill the

hole through the brush holder.(See photo 7). |

|

| 6. |

Next step is to drill a small hole so get

a small drill bit and tap set Size 4-40 and you're all done. |

|

|